Redesigned Zeroing Caps

MICRO

Objective

Improve measurement repeatability for a mechanical tensioning system by updating zeroing caps to hold parts in true zero position

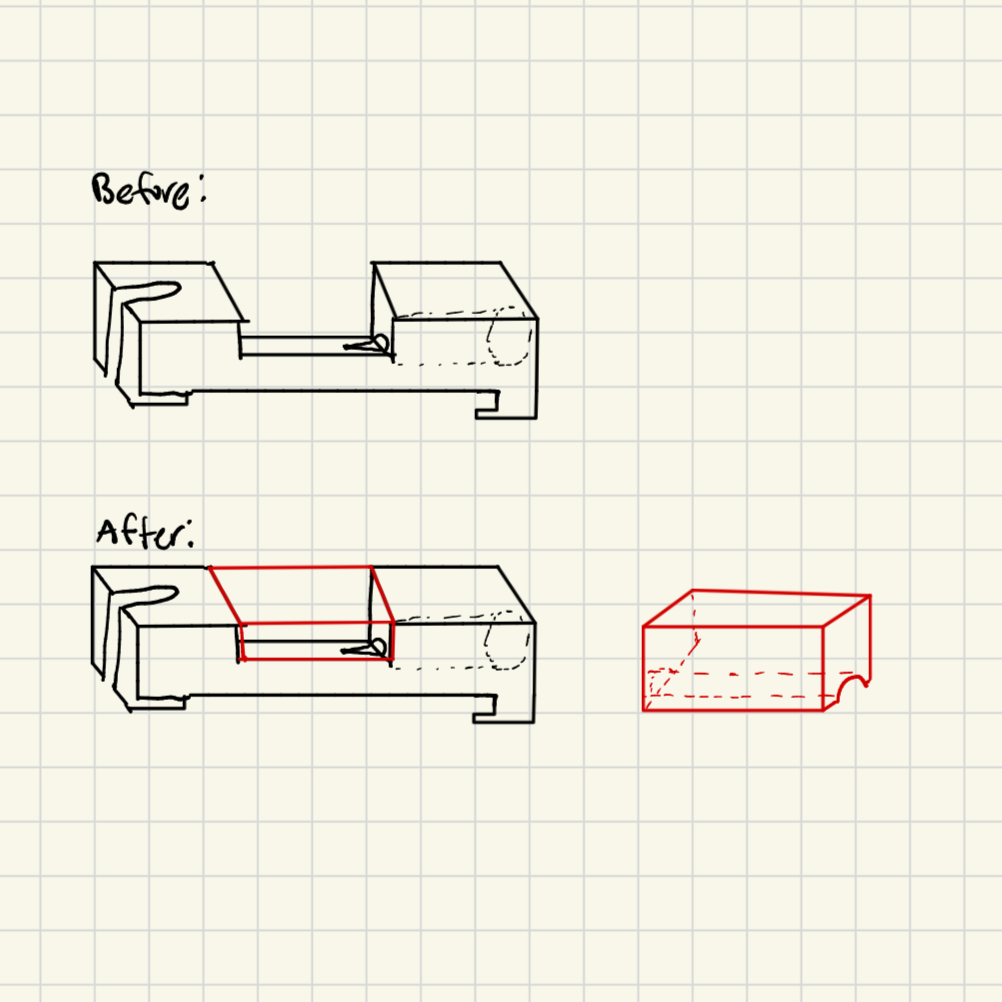

Concept Sketch

Performed root cause analysis to determine that inconsistent part seating was driving measurement variability

Redesigned zeroing caps to fully constrain the part geometry

Validated performance using SLA-printed biocompatible prototypes

How?

Results

Ensured consistent true zero alignment and reduced misalignment defects by ~30%